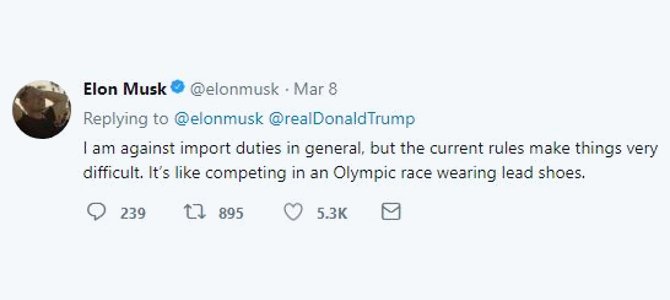

If “fake news” wasn’t already a zeitgeist-defining trope after the 2016 election, Elon Musk’s Twitter recent crusade against “the holier-than-thou hypocrisy” of journalists, editors, “big media companies” and the “clickbait” business model sealed the deal. Raging against the “incredibly dishonest” and “sanctimonious” journalists who have written critically about his management of Tesla in recent days, Musk promised to launch a website “where the public can rate the core truth of any article & track the credibility score over time of each journalist, editor and publication.”

Like Trump, Musk is clearly tapping into very real public concerns about the state of the media but his approach suggests that he is more interested in exploiting distrust in the media than fixing it. In a Twitter poll about his proposed rating site, he offered followers a choice between approving of his vague plan and voting “no, the media are awesome.” This false choice, between complete satisfaction with the status quo and total support for his “Yelp for Journalism,” betrays the true goal of his campaign: to pit his popularity against the rising tide of critical news stories about him and his companies, and force the public to make a choice. [ There is more … ]