When Californian electric carmaker Tesla floated the idea of a monstrous battery factory, christened “Gigafactory” by Elon Musk, it was true to the heart of every fan of clean energy. The company circulated pictures of a monstrous roof made all from solar panels. The trouble is, like so many things announced by Tesla, it may not be true.

The pictures of a Gigafactory decked-out in solar panels are still on Tesla’s website, but recent drone footage of the Gigafactory shows the battery plant devoid of any topside solar panels. There may never be any solar panels, a Gigafactory insider claims.

On the Australian auto site Carpoint, a commenter who says he works at the Gigafactory in Nevada, says that “despite Elon also owning Solar City, and the original plan to make the Gigafactory solar powered, that plan was permanently scrapped. “

Why the change of mind and roof? Follow the money. Would you invest big into solar panels if you can get large parts of your power for free? You might not, but Tesla does.

A filing with the SEC shows that as part of Nevada’s Thank You to Tesla for coming to the state, the company’s power bill will be substantially discounted.

According to the filing, which had parts redacted after Tesla requested “confidential treatment,” Tesla “shall be eligible for a discount to the base tariff energy rate portion of its electric power bill equal to: thirty percent in the first and second years of the contract, twenty percent in the third, fourth, fifth and sixth years of the contract, and ten percent in the seventh and eighth years of the contract.”

Nevada’s grid could use a little help from a massive solar installation. Its utility company, NVEnergy, is not known as the paragon of stable power, and even their on-line outage center experiences occasional outages.

The commenter confirms that “Nevada Energy, who supplies power to the factory, has always been notorious for being extremely unreliable with major outages in the entire area constantly.”

Tesla’s promises are likewise unreliable.

In January, Tesla told the press that it will “power its Gigafactory with a 70-megawatt solar farm,” using a vast expanse of solar panels that “will apparently be ~7 times larger than the largest rooftop solar system installed today.” When the Gigafactory was announced in 2014, Greentechnica said that “all told, the Gigafactory could actually produce 20% more energy than it needs on a daily basis.” A year later, Tesla walked that down a bit, telling Treehugger that the Gigafactory “will produce as much renewable energy as it uses.” Instead, that power will come off a quite dirty grid for the foreseeable future, if the insider is telling the truth.

Utility power may bring big savings for Tesla, but it also brings big problems, as the insider explains:

“Just a 3 second power failure, which happens there 2-3 times per week is an extremely major production killer to Panasonic who makes the battery cells inside the Gigafactory. The time it takes to get the equipment back up and running after even the slightest power bump is on average 6 hours. All battery cells produced for about 3-4 hours prior to the power bump also become worthless and must be disposed of. Millions of batteries end up unusable in the trash from just a 3 second power bump.”

Even if solar roofs don’t make economic sense, they would be beneficial to Tesla’s green image, and its overall credibility. The solar letdown is just one in a long series of Tesla’s tall tales and broken promises. Last week, Dailykanban published two reports on Tesla’s problems of getting the Model 3 produced in meaningful numbers. These stories triggered reports in the Wall Street Journal and other media, saying that “parts of Model 3 were being made by hand.” This would mean a sever disruption of Tesla’s ambitious production plans.

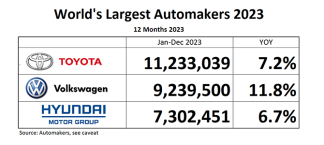

A knowledgeable source quoted by Wards Auto said “I can’t see them reaching 2,500 to 3,000 weekly until the end of next year.” Together with an assumed 100,000 Model S and X, Tesla’s total would then come out to 250,000 units per year, half of the 500,000 Tesla’s Musk repeatedly promised. A year ago, Dailykanban’s Ed Niedermeyer made a similar projection, based on government filings.

Meanwhile, the insider has a few more comments on the Gigafactory:

“The real delay to Tesla production is due to the battery cells not being manufactured to the true capacity they calculate being able to do on paper. This problem falls on Panasonic’s shoulders. When you factor in the initial problems I listed in my other post here you then have to factor in the Panasonic failures. Panasonic gave up attempting to produce the different cells used for the power walls, that’s why the Australian deal had to rely on Samsung not Elon’s own Panasonic cells being used.

1) I’d point out first that production is absolutely not being rushed or corners cut on quality just to meet promises. It’s the exact opposite. Panasonic takes the term “anal” to an entirely new level when it comes to product quality standards. I could write for days on the rigorous and extensive quality standards Panasonic lives by. If a single cell has even a microscopic scratch invisible to the human eye on the outside of the metal can the cell is rejected and sent to the trash. Production is then completely halted until the cause of that scratch is located and corrected. That’s just the cosmetic issues, I won’t even go into the measurement tolerances of every battery component that sends entire lots of components and almost fully finished cells into the trash daily.

2) Extremely poor quality management from the American side are a major problem with Panasonic as well. They don’t keep good talent and instead keep only warm bodies to fill seats that they deem easier to manage. These managers have no technical or production background and the first step Elon should demand is Panasonic dumps the management staff they currently have from production managers all the way down to the individual line leads.

3) The Japanese Technians Panasonic rotates in from their Japan plant are top notch and are at the heart of keeping any production going. The problem is these Technical Advisors (or TA’s as they’re referred to as within Panasonic) do not speak any English. Part of their role is to train the US based employees technical repair and maintenance of the production line equipment. This can’t happen because of the language barrier and the technical capabilities of the local people Panasonic has hired is non existent. This further goes back on the management for not weeding out the people who are technically incapable of ever performing true equipment troubleshooting or repairs. I’ve seen one of these incompetent “technicians” cause the production line to be down for days because he used a pair of channel locks to tighten a hex head bolt and completely rounded off the bolt head which then caused further equipment damage. Human caused problems like this from the Americans they hired as “technicians” are a daily problem with them doing more harm than good. Parts for any of the equipment they damage has to be shipped in from Japan to repair, nothing they use on that equipment is off the shelf or available anywhere in the US.

For Tesla to ever meet demands they’ll need to fix the limited access remote location problems. From Sparks, NV to the Gigafactory would be a prime location for one of Elon’s tunnels. It’s that or build affordable apartments close to the facility.

They’ll need to solve the unreliability of power supplied from Nevada Energy (even though the factory is only a few miles away from the power plant). That can be fixed by bringing back the idea of solar power and back up battery power supplies. Nevada Energy only progressively gets worse in unreliability, there’s no hope they’ll ever get better.

They’ll need to fire from the top down all the current American management at Panasonic, none of them are “keepers”. Bring in managers from the Midwest or other areas who have actual production experience.

Restructure Panasonic’s technical employees. There needs to be a top down management team from manager to technical lead devoted solely to technical issues and repairs. Get rid of the current people Panasonic’s incompetent managers have brought in as “technicians” that do more harm than good. Again the available pool of people in this area capable of performing actual technical skills is extremely limited so again they’re going to have to attract in people from outside the area to fill these positions.

I could make a longer more detailed list easily but I think you get the point.”