As the maker of tailpipe-free electric vehicles, Tesla is perhaps the last auto manufacturer you’d expect to struggle with an NOx emissions problem. Yet like any other auto manufacturer, Tesla operates factories which produce a variety of emissions including the NOx carcinogens at the center of the recent Volkswagen scandal. In fact, Dailykanban has discovered that Tesla has self-reported an NOx noncompliance at its Fremont, CA factory that may be contributing to delays in the production of the firm’s new Model X SUV.

On November 13, 2014, Tesla received a Notice of Violation from the Bay Area Air Quality Management District (BAAQMD) when it self-reported non-compliant NOx emissions at a thermal oxidizer at its Fremont plant identified as A-1002. In BAAQMD’s report to the EPA on the issue, the local regulator confirmed that A-1002 was non-compliant with the allowable NOx emissions level of .1 pound per million BTUs of thermal input specified on page 168 of Tesla’s BAAMQD permit for its Fremont plant.

Known as the Truck ED-Oven Thermal Oxidizer, A1002 uses up to 10 million BTU per hour of natural gas power to incinerate Volatile Organic Compound (VOC) pollutants produced by the plant’s paint shop oven and cooling tunnel at 1400 degrees Fahrenheit. Confusingly, a Thermal Oxidizer for the same pollution source known as A10022 was permitted to replace the previous oxidizer A1002 (see page 42) in 2004 when the Fremont plant was still a joint-venture between GM and Toyota known as NUMMI. But in the notice of noncompliance to the EPA and Tesla’s current permit, the code for this source was reverted to A1002, with BAAMQD calling the renumbering a “typographical error.” In any event, the oxidizer’s noncompliance does not appear to have been a problem with VOC destruction, but rather the overproduction of NOx by the natural gas incinerator.

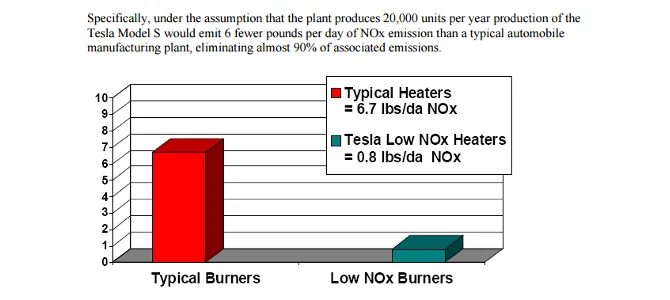

Given a 10 million BTU/hour maximum rate for A1002, noncompliance with the .1 lb of NOx per million BTU would imply production of a pound of NOx every hour at maximum operation. Precisely how much NOx Tesla’s Fremont plant has emitted due to this noncompliance is not clear, as it depends on how much use the thermal oxidizer saw. Still, in a request for $320 million in state tax breaks for the plant (approved before the Fremont site was chosen) Tesla claimed that its planned use of “innovative ‘powder paint'” would reduce NOx emissions by 90% compared to a “typical automobile manufacturing plant”. At 20,000 units per year of production, Tesla estimated its plant’s NOx emissions would be just .8 pounds per day. Given that A1002 alone could produce up to one pound of NOx per hour at compliant levels, it seems unlikely that Tesla’s Fremont plant actually produces less than one pound of NOx per day, especially with A1002 in a state of non-compliance.

Beyond the obvious concerns about NOx emissions themselves and accountability on promises made about them to secure state tax breaks, the non-compliance of A1002 raises questions about the delays that have plagued Tesla’s Model X. Tesla management’s comments about Model X delays have all centered around design and manufacturing challenges, with CEO Elon Musk especially emphasizing the vehicle’s complexity and calling it “the most difficult car in the world to build.” In the last quarter’s conference call, Musk continued to emphasize the product-related challenges associated with Model X production, saying:

I mean they are really down to like the little things, like the placement of the seal on the door and whether that results in the bright trim alignment being correct, this is quite nuanced…

…Door seals, right now, is a challenge, for example. The monopost seat in the second row is still a challenge, but less of a challenge. It’s not the gating factor. This is basically going through a series of constraints. Most constraints can change from one day to the next. But the important point is that we don’t see any fundamental obstacle to achieving a production rate of several hundred per week sometime next month.

But there’s reason to believe A1002 may be playing an undisclosed role in Model X delays. In compliance documents A1002 is identified as being part of the “truck” paint shop and Model X is reportedly being “assembled on the former site of the Toyota Tacoma,” which strongly suggests the non-compliant oxidizer primarily affects the production line for the delayed Model X but not the Model S. Furthermore Tesla’s schedule of compliance for A1002 indicates that the oxidizer will not be compliant until January 30 of 2016, because Tesla is refurbishing a replacement oxidizer rather than purchasing a new unit. That timeline matches Musk’s statement that

I think it’s likely that we could be in that 1,600 vehicles to 1,800 vehicles range, per week range, in Q1. I mean, I’m guessing we’ll probably be towards the lower-end of that range, but then maybe exceed that, the high-end of that range, towards the end of next year if things go well.

Musk’s emphasis on the flashy features of the Model X and his consistent portrayal of production challenges as being related to suppliers and product execution conceal the potential impact of A1002’s non-compliance. But unlike the challenges Musk is willing to discuss, which are vague and not tied to any specific dates, the refurbishing of A1002 provides a concrete explanation for why Model X production might be constrained through the end of this year but able to ramp up in Q1 of 2016.

Tesla has not yet responded to Dailykanban‘s request for comment on these issues, but we will update this post as soon as they do.